DualSun panels are designed to produce maximum electricity, with the minimum impact on the environment.

The whole range is low-carbon certified, meaning that a DualSun panel emits less CO2 than a standard solar panel. The term low-carbon is used here to qualify photovoltaic solar panels whose carbon footprint is less than 550 kg eq. CO2/kWp, according to the Simplified Carbon Assessment methodology and a limit defined by the state.

At DualSun, we have chosen low-carbon for 100% of our panels in order to produce the greenest renewable energy possible, but also because we believe we have a role to play as a French industrial company in the continuous reduction of our carbon emissions.

Carbon footprint measurement at DualSun

The carbon impact linked to the production of the panel

Carbon emissions linked to the production of a panel are measured from the extraction of raw materials to assembly thanks to the Simplified Carbon Assessment.

This assessment is used by Certisolis to certify panels whose production-related carbon emissions are less than 550 kg CO2 equivalent per kWp, and it is necessary for projects from 100 kWp to 500 kWp in France to obtain a purchase price. on the electricity produced.

The simplified carbon study results of our DualSun panels are available on our website: Technical documentation EN – DualSun

A little reminder of the received ideas to be deconstructed on the carbon footprint of photovoltaic panels:

- No rare earth is not used for the manufacture of a panel: It is a received idea that dies hard, but the manufacture of a solar panel never uses any rare earth (precise list of 17 minerals whose extraction is very polluting). The main component of a panel is silicon, the second most abundant element on Earth, after oxygen.

- Crystalline silicon panels are recyclable : More than 94% of the panel is recycled on average, the remainder being mainly plastic which remains an element to be optimized in the future. Recycling is carried out in France by SOREN, an independent non-profit organization.

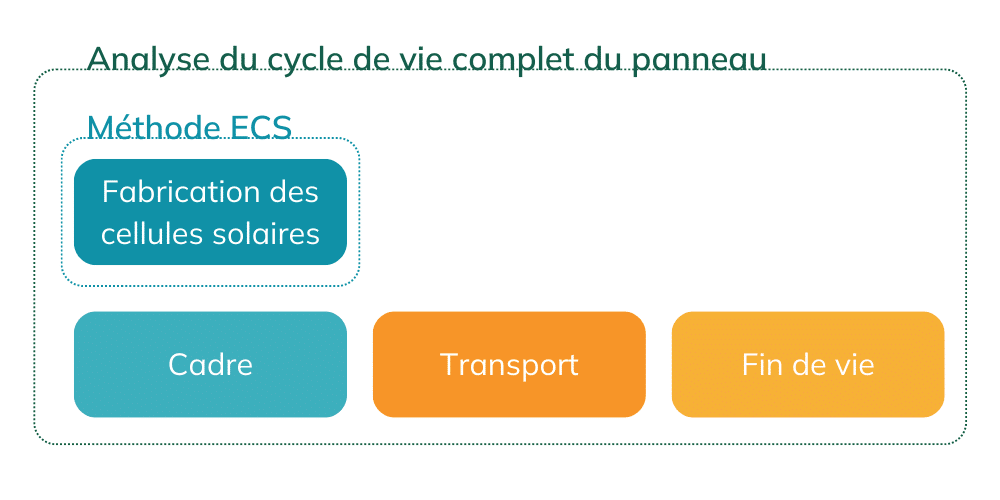

A more comprehensive impact measurement with panel life cycle analysis

DualSun has further extended the measurement of the carbon footprint of its photovoltaic panels, by measuring the impact of the manufacture of the frame as well as the transport and ther ecyclingof the panel.

> To find out more: The manufacturing steps of a photovoltaic panel are detailed in this article.

The carbon footprint of a panel has thus been broken down according to the different stages of its life cycle, to measure and identify possible impact reductions:

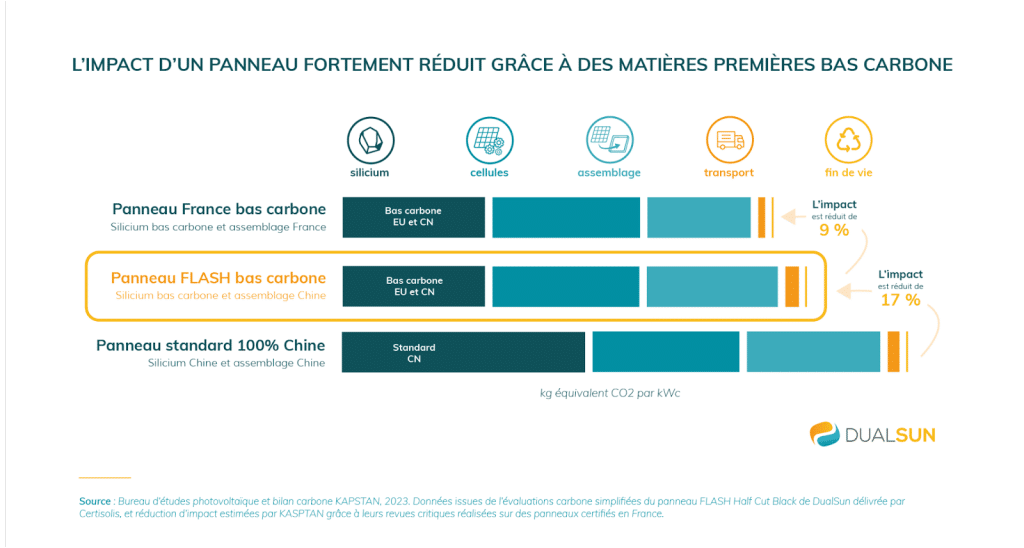

- Making of silicon, which can represent up to 45% of the impact of a panel, has been improved as a priority thanks to the choice of a low-carbon silicon.1/3 of the silicon comes from an optimized manufacturing process, in order to reduce the extraction of raw materials. There is therefore a silicon manufacturing impact of 197 kg CO2 equivalent per kWp, compared to 314 kg for a non-low-carbon silicon: which allows a reduction of carbon impact of the panel by 17%.

- Lamination step, which consists of assembling the different layers of the panel together, would mean a global gain of 9% if it was made in France (reduction of impact on lamination and transport). This is an element that we continue to study for the future evolutions of our production process.

- Transport from the manufacturing plant in China to France has an impact that we follow carefully, but represents only a part 2 to 3% of the footprint of a panel.

The carbon footprint of a photovoltaic panel according to different production scenarios

Methodology

This impact study was carried out by KAPSTAN, using “method 2” defined by the Energy Regulation Commission in the specifications of the order of April 6, 2021.

The data comes from simplified carbon assessments of FLASH panels from DualSun and from average impact calculations in France from KASTAN thanks to their critical reviews of panels certified in France.

We have chosen to complete this carbon footprint with another multi-criteria analysis methodology, using the PEP method ecopassport®.

The scope of this method is also extended to the impact of the frame, transport and end of life for a complete analysis of the product life cycle.

Measurement of carbon and energy performance

The carbon performance of the energy produced

To make a complete carbon balance, it is interesting to measure the carbon savings that the panel will subsequently achieve. We compare the carbon emissions related to manufacturing, and the savings we make afterwards, to measure the carbon performance of the installation. It is measured in grams of CO2 equivalent per kWh of energy produced, for all of our panels:

- 20 to 22 grams of CO2 equivalent per kWh for the panel alone on the FLASH range, and 12 grams CO2 for the SPRING: It is an excellent score, at the top of most panels available on the market (20 to 30 grams*).

- 16 grams of CO2 equivalent per kWh for the rest of the equipment and installation site, which are often omitted from the analyzes even though they represent here 45% of the carbon footprint of a photovoltaic installation: we have chosen to include them in the calculationof all our indicators.A DualSun installation thus emits 28 to 38 gCO2e/kWh depending on the panel model chosen. * Nouha Gasbour, CEA,on the sustainability of photovoltaics

To improve the performance of the installation, one of the best levers remains, however, to favor an installation in the rules of the art to optimize production, with an installer trained and accompanied on all products.

A lower impact than the French electricity mix!

This indicator makes it possible to compare the equivalent quantity of CO2 emitted per kWh of energy produced by different energy sources.

A power plant made up of DualSun FLASH panels for residential and self-consumption emits from 28 to 38grams of CO2 equivalent per kWh. Thus, at the national level, DualSun technology significantly reduces CO2 emissions and contributes to low-carbon renewable energy in France:

Average electricity mix by source and by country(gCO2éq/kWh)

Source : ecoinvent, Electricity Maps, environmental impact assessment reference system (ADEME)

Photovoltaic energy is an essential element for the construction of the energy mix of tomorrow in France, which involves several levers:

- The production of solar energy homes contributes to reduce consumption on the electricity grid, as recommended by RTE in France to increase from 1,600 to 930 TWh per year,

- The increase in solar production makes it possible to support the electrification of our consumption, while electricity should no longer represent 25% but 55% of the energy consumed (notably due to our now electric vehicles),

- Solar energy participates in drastically reducing electricity of fossil origin replacing it by renewable and low-carbon energy.

Methodology

The calculation of the production was carried out for each panel taking into account an average irradiation of 1400 kWh/m²/year corresponding to the city of Lyon over a period of 30 years, a standard performance ratio of 75%, as well as the guaranteed minimum yield and the annual yield loss for each panel as indicated in the technical data sheets of the products accessible on the Technical documentation EN – DualSun.

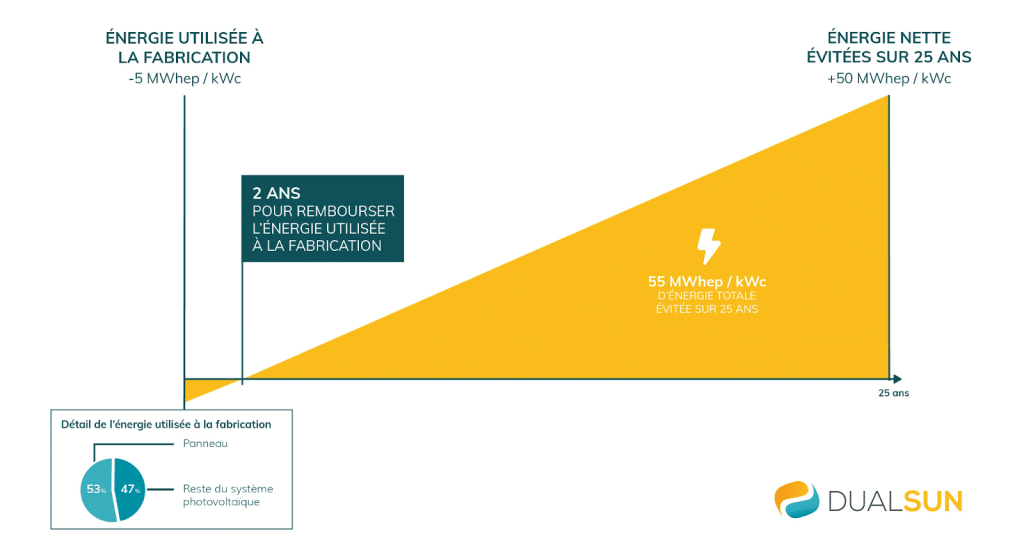

An energy payback time of 2 year

In addition to performance carbon, we measured how long it takes a DualSun solar panel to produce more energy than was needed for its manufacture. We used the Product Environmental Profile® (PEP) of the DualSun FLASH 410 Half-Cut White panel to measure this energy payback time:

- 87800 MJ/kWc, meaning 2417 kWhep/kWc of primary energy was necessary for the manufacture of a panel (primary energy – denoted kWhep – takes into account all the energy necessary for production, including losses linked to the transformation and transport of electricity: this is therefore the real impact of our energy).

- If we also consider the manufacture of the inverter and the electrical connections as well as the installation and maintenance of the panel, a total of 4611 kWhep/kWc of primary energy is expended,either 4.6MWhep/kWp.

- Each year, the module produces an average of 960 kWh/kWp in France, which corresponds to 2207 kWhep/kWp of primary energy, i.e. 55,2 MWhep/kWc over 25 years (in fact, approximately 2.3 kWh of primary energy is needed to produce 1 kWh of final energy used at the point of consumption in France, according to the RE 2020 standard. This coefficient may vary depending on the country).

Finaly, the energy payback time for the complete installation (and not just the panel) is two years.On the basis of a period of use of 25 years, a solar installation therefore reimburses the energy consumed in the first two years and allows net production during the following 23 years.

The energy return of a DualSun FLASH Half-Cut White installation

The challenges of the energy transition

The “energy future” foreseen by RTE in his report 2022 plans to increase electricity production in France using low-carbon energy sources, including photovoltaics.The objective is therefore not to replace a source of electricity production with photovoltaics but to produce more electricity to reduce our consumption of fossil fuels.. Without a massive development of renewable energies, it would not be possible to have enough low-carbon electricity in France to meet our climate objectives.

Share of electricity in final energy consumption in France 2021 – 2050

1. renewable energy excluding electricity, waste, heat, 2. Electricity, 3. Fossil fuels 4. carbon-free gas, 5. of which hydrogen produced from electricity

Source: “Energy Futures 2050” study, RTE, 2021

It’s a fact: tomorrow more electricity will have to be produced to meet demand, even when reduced by 40%. We are not replacing nuclear with solar, but we must produce more electricity. Doing without solar energy for this will not make it possible to achieve the objectives set by the government to reduce fossil fuel consumption.

The climate impact of additional photovoltaic solar capacity in France (ENERPLAN study, March 2020)

The production mix replaced by PV was calculated through detailed modeling of the French and European electricity system.

As France is interconnected with its neighbours, production is affected not only in France but also in the rest of Europe. This additional production can, depending on the moment, replace production in France, leading overall to a reduction in CO2 emissions, or affect border flows, by increasing exports or reducing imports, thereby affecting neighboring mixes, and therefore potentially their emissions.

CO2 avoided by 1kWh of photovoltaic energy produced in France

1. Reduction in gas power plants in France,2. Decline in fuel oil power plants in France,3. Decline in European coal / lignite,4. Fall in European gas,5. Decline in European fuel oil

Conclusion

At a time when buildings account for more than 35% of global energy consumption, DualSun aims to make buildings energy self-sufficient. We work every day to develop a technology that is specifically suited to the electricity and heat needs of buildings.

Aucun commentaire.

Leave a comment

Votre adresse e-mail ne sera pas publiée. Les champs obligatoires sont indiqués avec *